Introducing our product-specific carbon footprint

At Outokumpu we have taken our open communication on sustainability to the next level by becoming the first stainless steel producer to provide a product-specific carbon footprint. This information, based on continuous production data, is part of our commitment to helping our customers to reduce their climate emissions.

There is a growing need for companies to reduce all indirect emissions from their value chain. In fact, many are already calculating and reporting direct and indirect emissions. However, to calculate the complete CO2 emissions down the supply chain it is essential to know the CO2 impact of the materials they buy in – and that’s why this product-specific information is vital.

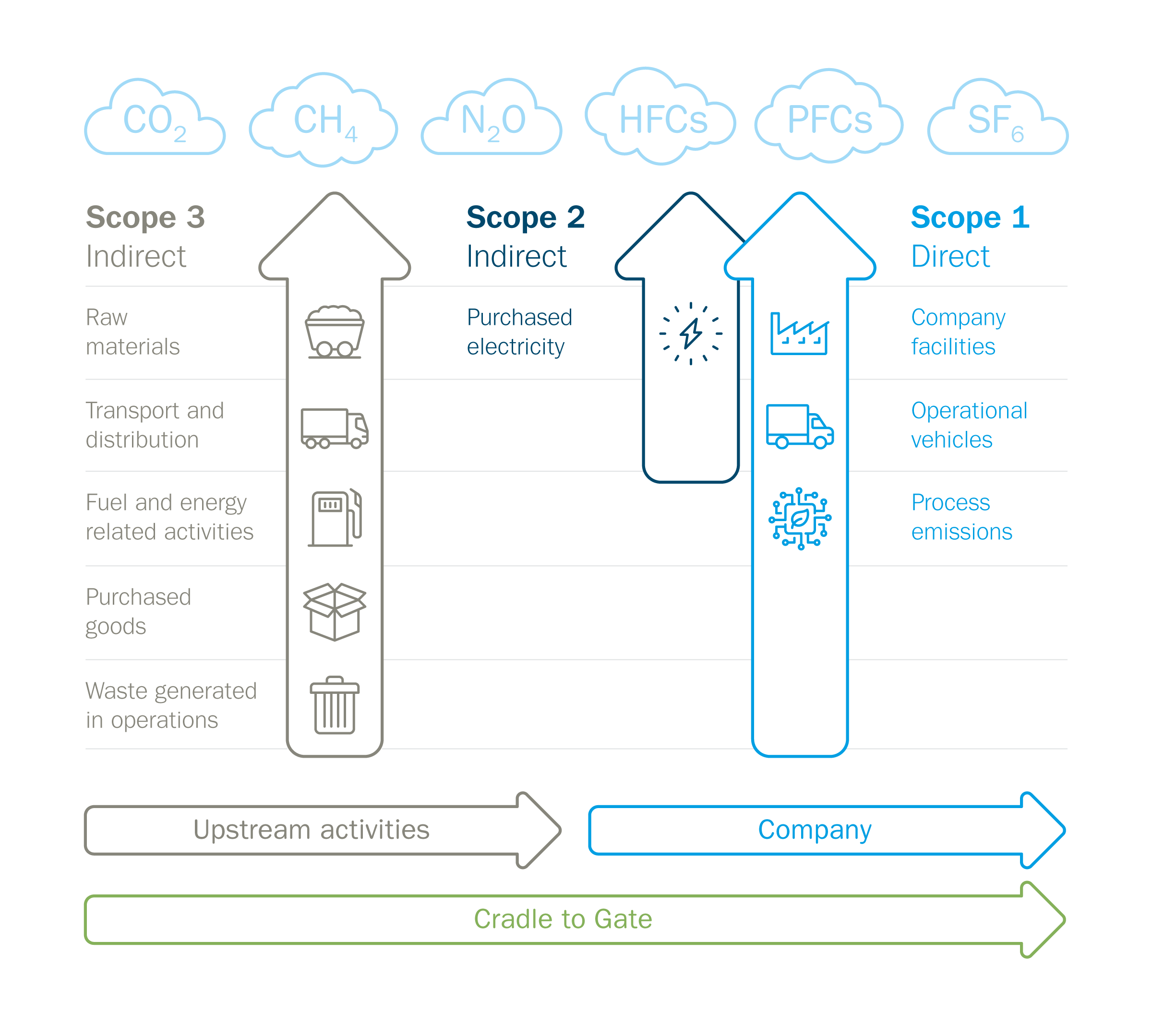

Outokumpu is in a great position to support manufacturers as we have a leading role in using recycled material for over 90% of our global production on average. In addition, our reporting is extensive and above industry average: we report all three emission scopes (please see the picture below).

Making this specific data available means that our customers no longer need to rely on average industry figures for their own carbon footprint calculations. Instead, most of the batches of steel grade we produce comes with its own carbon footprint certificate. The distinct feature of the calculation model we use is based on continuous follow-up of production data.

This is a very significant development that will help customers in their emission-reduction goals and support Outokumpu’s long-term climate targets and sustainability strategy.

Full scope 1-3 cradle to gate

Within our calculation, we are considering all Green House Gas (GHG) emissions through the whole production chain (Scope 1, 2, 3) and are following the Cradle to Gate approach. Within our approach, end-of-life values are not included to increase transparency.

The yield of each production is included. The values which will be printed are based on a 12 month rolling average and will be updated in a monthly interval. For the emission factors that we used for the input materials, we were relying on data mainly from the Ecoinvent database, but also from Worldsteel or other relevant industry associations.

PCF added to product certificates

Outokumpu customers can find the carbon footprint for most of the products on their product certificates alongside other properties such as yield strength, tensile strength and elongation, which are universally recognized as mechanical properties.

With this information we want to help our customers to reach their own climate initiatives.

Cutting emissions by 42% by 2030

Outokumpu’s own climate target is to reduce carbon dioxide emissions by 42% by 2030 from the base year of 2016. This translates to an emission reduction of 14% by the end of 2025 from the 2021 levels, in accordance with the Science-Based Targets initiative’s 1.5 climate target. We are the only producer of stainless steel with a climate target approved by the initiative.